Bedge65 Build Guide

Congratulations on the purchase of your Bedge65!

This guide will take you through all the steps required to complete your Bedge65.

This guide is a work in progress.

Firmware

Components

- 1 x Bedge PCB

- 4 x 3mm Acrylic Case Pieces

- 1 x 4.5mm Acrylic Case Pieces

- 3 x 3mm Acrylic Feet

- 4 x Aeboards Feet

- 6 x 12mm Brass stand-offs

- 3 x 14mm Brass stand-off

- 3 x 6mm Brass stand-offs

- 20 x 5mm Torx screws

- 3 x 6mm Torx screws

Additional Parts Required to Complete

- Pro-Micro Controller (Sea-Micro/Nice!Nano)

Optional Parts

- Female-Male Machined Pin Headers

- Mill-max Pins or Diode Legs

- LiPo Battery (If using Bluetooth)

Tools Required

- Soldering Iron

- T5 Torx Driver

- Solder

- Flux (I prefer the paste)

- Tweezers

Steps

Diodes

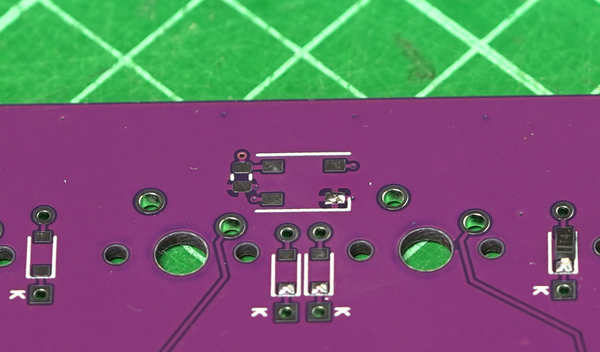

Prepare by tinning one pad for each of the diode positions. You can use a little flux here to make the solder flow easier if required.

Using tweezers place one diodes in place and heat the tinned pad to attach the diode. Note the orientation of the diode! The end with the thin white line is the Cathode and it should face south (Towards the K).

Complete this step for all diodes.

RGB LEDs

As with the diodes, tin one of the 4 pads of each LED position. Once done apply flux to all 4 points.

Change the heat of your soldering iron to about 300 degrees – LEDs are sensitive to heat and too hot an iron can kill the LED.

Orientate the LED correctly, with the diamond on the LED towards the L of the silkscreen. Attach the LED by heating up the tinned pad and holding the LED in place. Make sure to push the LED down to ensure it is flat against the PCB.

Solder the other 3 points of the LED as per usual. While this can be done without flux, it is much easier with flux as the solder flows much more easily.

Pin Headers for Pro Micro (Optional)

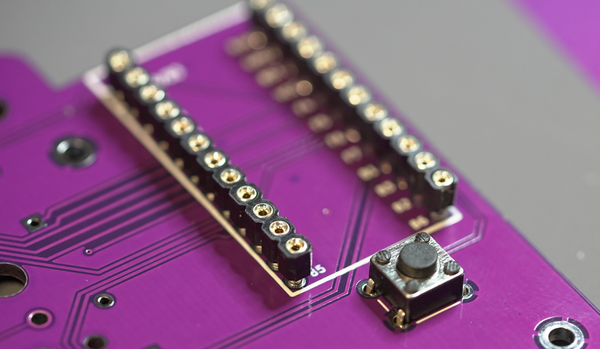

While pin headers are optional, it is highly recommended that you socket your MCU if you plan on change it in the future. For battery installations, the Pin headers are mandatory so you can get access under the Nice!nano.

Ensure that the pin headers are straight by soldering one pin on each row and checking for alignment before soldering all other pins.

Insert Mill-Max pins or diode legs – Push down on each pin to ensure the pin engages in the socket.

Place the MCU on top and solder in place. Components should be facing outwards.

Reset Switch

Insert the reset switch and solder the 4 pins from the rear.

Install Firmware and Test

If using Pro-Micro , Sea-Micro or other compatible Device

Install QMK toolbox – Flash Firmware

Install Via Software - Sideload JSON

Test switch positions with a pair of tweezers.

Install switches

Stack 4.5mm plate on top of PCB. Make sure you peel of the plastic protective covering on the acrylic!

Install switches through plate onto PCB. Solder switches at the rear.

Stabilizers can be installed before or after this step - the plate cutouts are large enough that stabilizers can be removed even after the board has been soldered.

Assemble Case

Attatch the brass stand-offs onto the PCB as per the image below. Screw them in from the back using the provide 5mm M2 Torx Screws.

There are 3x 6mm stand offs that will attatch on the opposite side. These are for the feet.

Note: There are 3 x 6mm M2 screws you will use later for the pro-micro covers. Make sure you are using the 5mm screws.

Add the first layer

Add second layer (with PCB)